Load & Haul Intelligence Built for Smarter Mining

Detect oversize, monitor shocks, assess roads, and improve truck cycles - all in one platform.

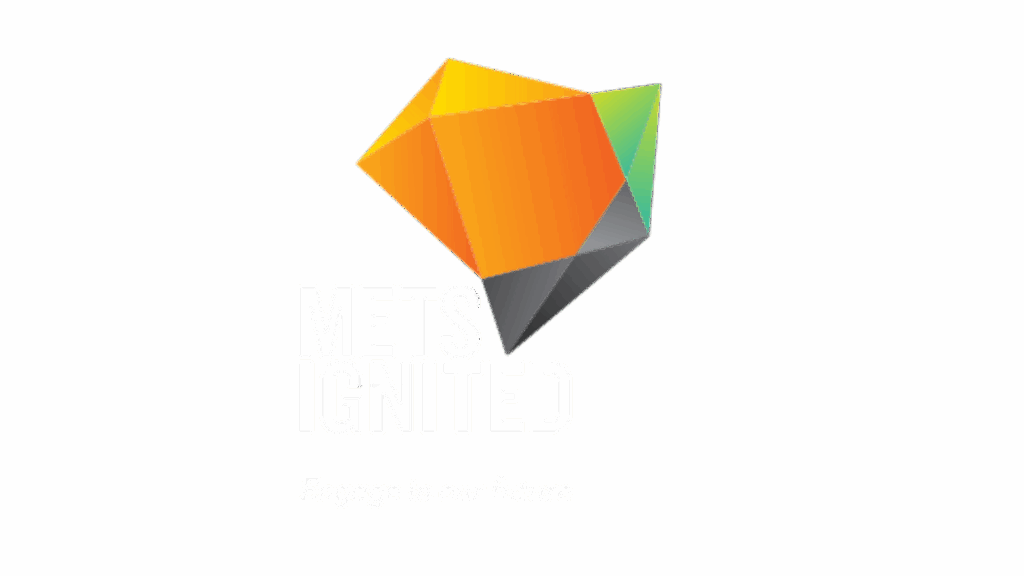

Minimise downtime by detecting oversized rocks

Oversized rocks can cause blockages in the primary crusher.

LoadWise detects oversize rocks during loading and reduces unplanned stoppages.

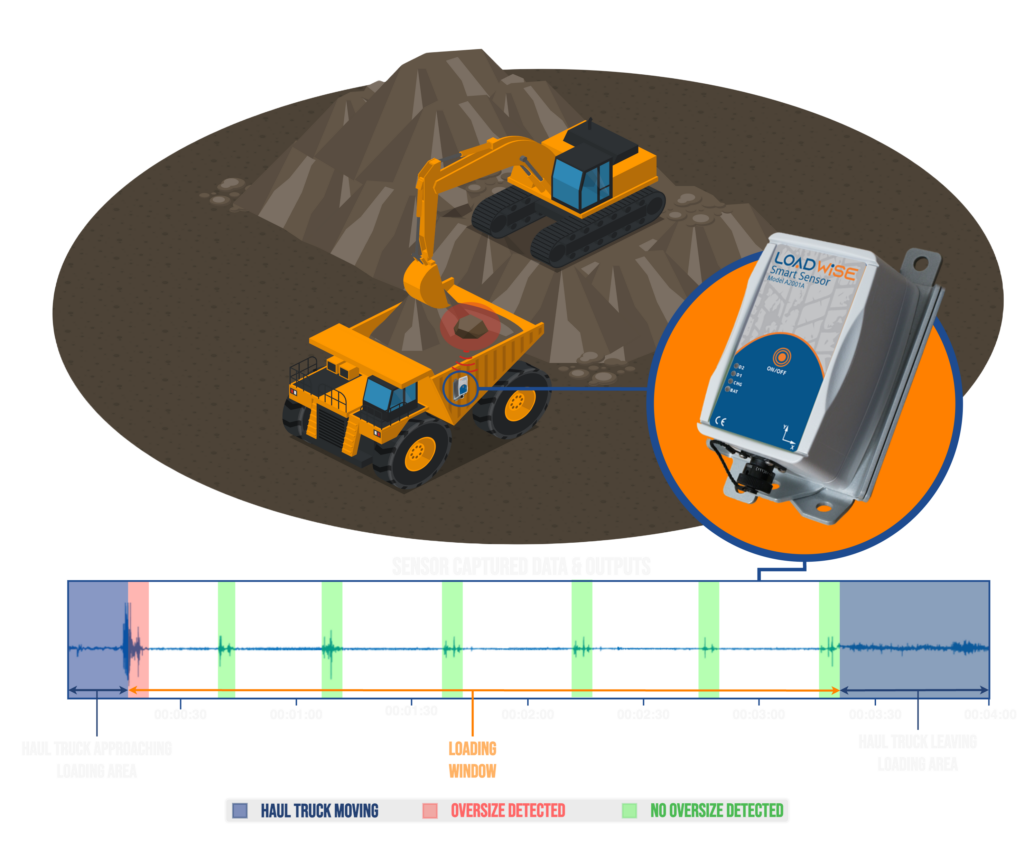

Maximise equipment life by detecting wear-causing shock & vibration

Excessive exposure to shock events can exacerbate equipment break-down and cause injury to truck operators.

LoadWise provides insight into operational conditions that lead to equipment wear and helps extend asset life.

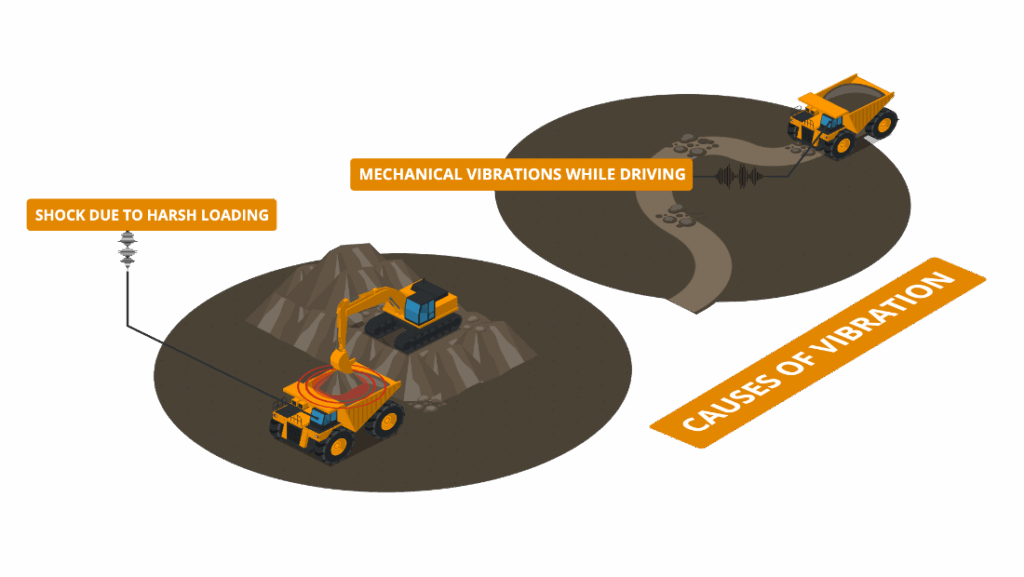

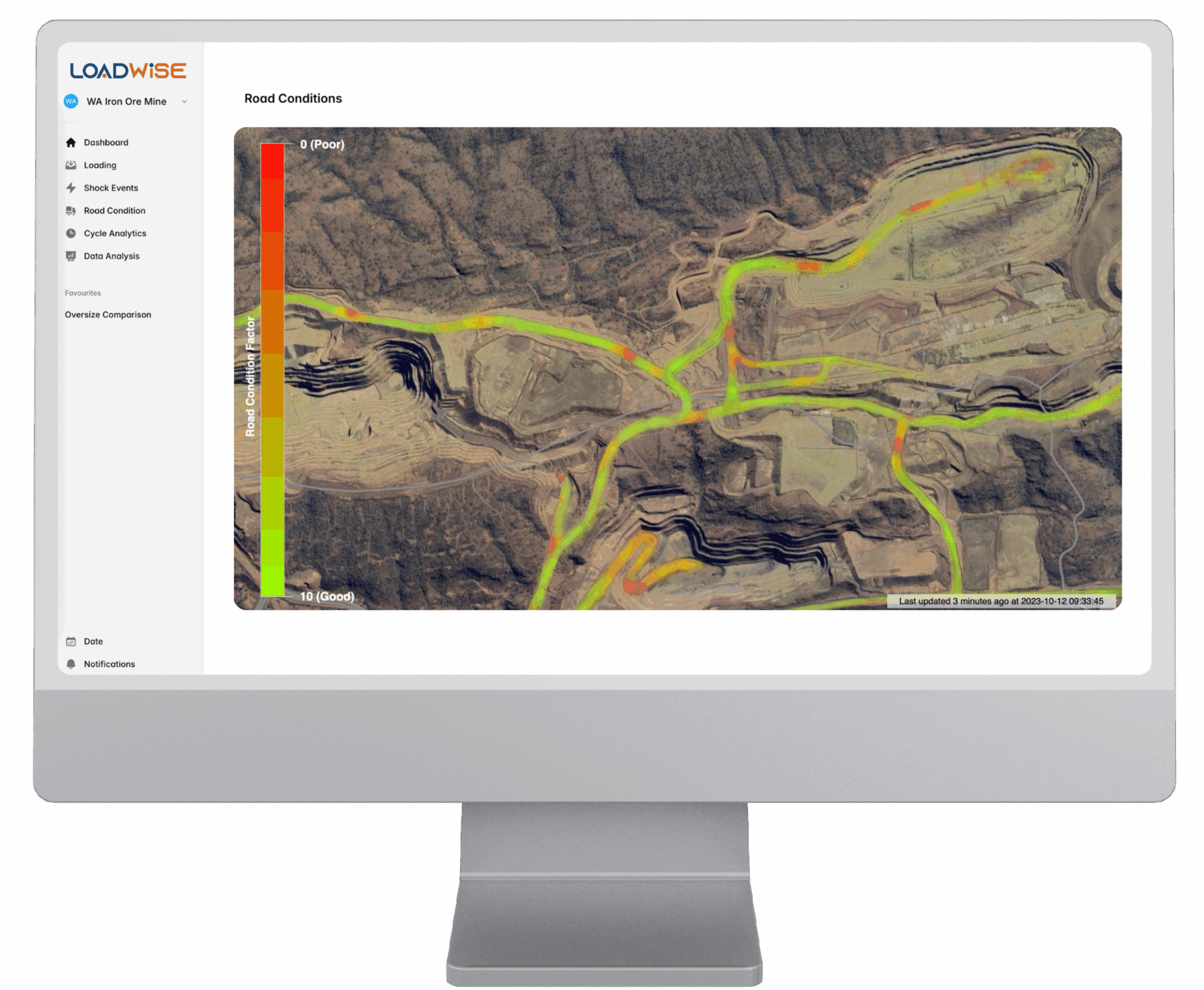

Boost productivity and streamline maintenance by monitoring road conditions

Poor road conditions lead to excess wear and tear of mobile plant and sub-optimal cycle times.

LoadWise identifies deteriorating road conditions to improve cycle times, reduce tire wear, and streamline road maintenance.

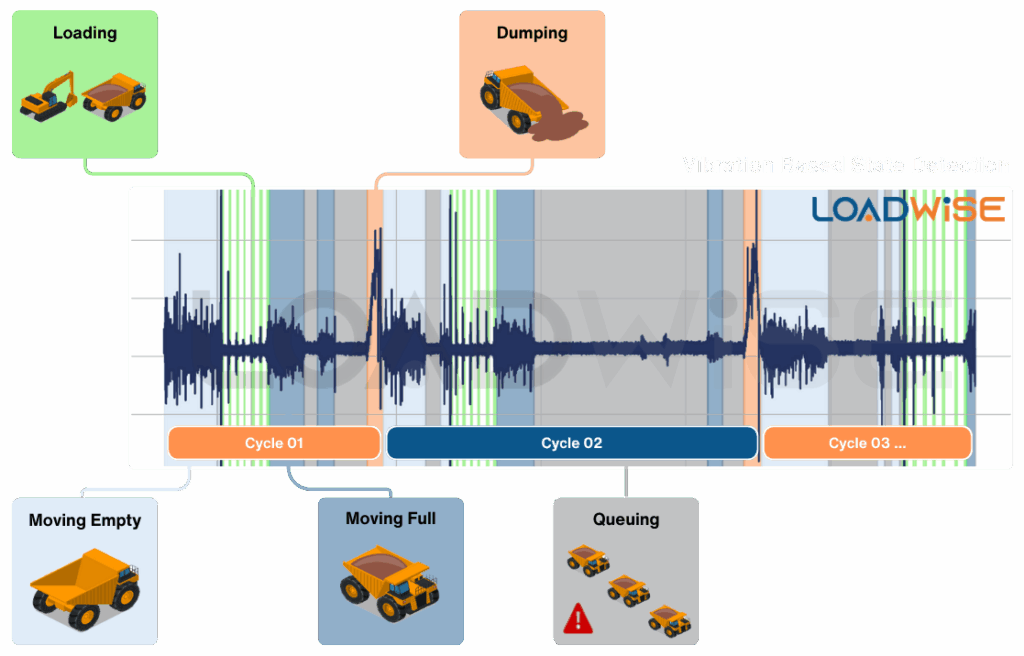

Improve scheduling by monitoring truck cycles

Failure to address poor truck cycle-times in a timely manner leads to missed production targets

LoadWise tracks truck movements to optimise cycle times, reduce fuel use and improve scheduling.

The Technology Behind LoadWise

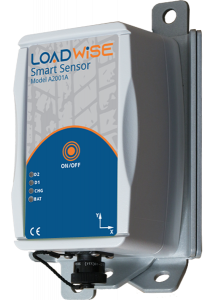

Sensor Node

Vibration measurement device used to capture truck load and haul events.

Features

Ruggedised IP67 design, Quick & Easy Magnetic Mounting, Integrated Data Logging, Extended Battery Life, Edge Processing

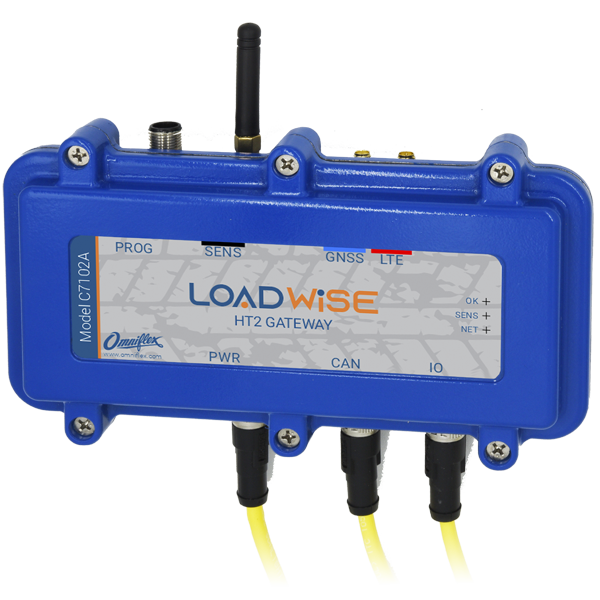

Gateway

Connectivity device that captures GNSS data, aggregates sensor node and CAN measurements, and transmits all information to a cloud or local server.

Features

GNSS Enabled, Multiple communication mediums and channels e.g., MODBUS, CANBUS, Ethernet, 4G/LTE, BLE

Dashboard

An online portal to remotely access insights, key metrics and analytics derived from uploaded data.

Features

Real-time/historic data for haul truck loading, Fully searchable logs (e.g., loading events), Interactive geospatial plots, Real-time alerts & more.

Case Studies

Context

Haulage operations are complex and often riddled with hidden inefficiencies that impact productivity and cost.

Problem

In a typical 10-hour shift, trucks spend a significant portion of their cycle time waiting—especially queueing before loading. This idle time is rarely visible but has a real impact.

LoadWise Implementation

Using LoadWise, an instrumented truck was monitored over 29 cycles, revealing a median cycle time of 1211 seconds. It was found that approximately 5% of each cycle was spent queueing before loading.

Benefit

By identifying and quantifying queueing delays, LoadWise allows planning and dispatch teams to streamline operations, reduce idle time, and boost overall haulage efficiency.

Context

Excavator performance is a key driver of loading efficiency and overall site productivity.

Problem

Loading operations underperform due to inconsistent excavator cycle times and operator variability. This gap between actual and potential throughput limits site productivity.

LoadWise Implementation

Excavator cycle data captured by LoadWise revealed cycle times ranging from 15.8 to 59.7 seconds, indicating a theoretical maximum throughput of 4,921.5 tonnes/hour. However, the observed median performance was only 2,484.3 tonnes/hour. Further analysis showed that operator performance significantly influenced outcomes, with some cycles underperforming the median by up to 35.6%.

Benefit

These insights highlight clear opportunities for targeted operator training and performance optimisation, helping unlock higher productivity and more consistent loading efficiency.

Context

Poor haul road conditions can reduce productivity by slowing trucks and increasing wear and tear.

Problem

Degraded road segments cause slower truck speeds and more frequent shock events, leading to longer cycle times and reduced throughput.

LoadWise Implementation

LoadWise analysed vibration data from haul trucks to pinpoint segments with severe jarring and potholes, directly linked to high-impact shock events and speed reductions. A 7.8% drop in road condition led to an 8.3% decrease in unladen truck speed, increasing cycle times and lowering overall productivity.

Benefit

These insights enable targeted road maintenance, transforming upkeep into a data-driven process that boosts efficiency, reduces delays, and supports smoother operations.

Context

Oversized material causes major downtime and production loss in large-scale mining.

Problem

Oversize events disrupt crusher operations, reducing throughput and revenue.

LoadWise Implementation

At a 50 Mtpa iron ore mine in Western Australia, oversize rock blockages contributed to 370+ hours of downtime and ~2 Mtpa lost output, worth up to USD $200 million annually. LoadWise detected oversize with 70–90% accuracy, validated by camera footage.

Benefits

These insights enable proactive oversize management, with the potential to recover between USD $140 million and $180 million annually for the site.